Energy Storage Spot Welding Machine

Energy storage spot welding machine is a device that uses energy storage capacitors to discharge heat and achieve spot welding connection of metal parts. It is widely used in fields such as battery manufacturing, electronic components, and automotive parts.

|

Comparison Dimension |

Energy Storage Spot Welder |

Traditional AC/DC Spot Welder |

| Energy Source | Energy storage capacitor discharge (pulse-type): Stores energy from the grid into capacitors through slow charging and releases pulsed energy instantly during welding. | Direct grid power supply (continuous-type): Draws power from the grid continuously during welding, relying on stable grid voltage. |

| Welding Time | Millisecond-level (1–100 ms): Completes welding in ultra-short time with extremely low heat input. | Hundreds of milliseconds to seconds: Relatively slow welding process with obvious heat accumulation. |

| Heat-Affected Zone (HAZ) | Small: Concentrated energy and short action time result in narrow welds and minimal thermal deformation, suitable for precision components. | Larger: Continuous heating may cause local high temperatures in workpieces, potentially leading to deformation or annealing. |

| Grid Impact | Low: Stable current during charging (e.g., phased charging), and short-duration pulsed current during welding causes minimal grid fluctuations. | High: Instantaneous high current (up to tens of thousands of amperes) during welding may cause sudden drops in grid voltage, requiring a dedicated power distribution system. |

| Application Scenarios | Thin-walled parts (e.g., 0.1–2 mm metal foils, electronic component leads), high-precision requirements (e.g., lithium battery tab welding), automated production lines (compatible with high-speed welding robots). | Thick plate welding (e.g., steel plates over 3 mm), non-continuous production scenarios (e.g., maintenance, small-batch processing), and occasions with low requirements for welding speed. |

Heltec Full Range of Spot Welder

Battery Spot Welder 01 Series

Battery Spot Welder 02/03 Series

Laser Welding Machine

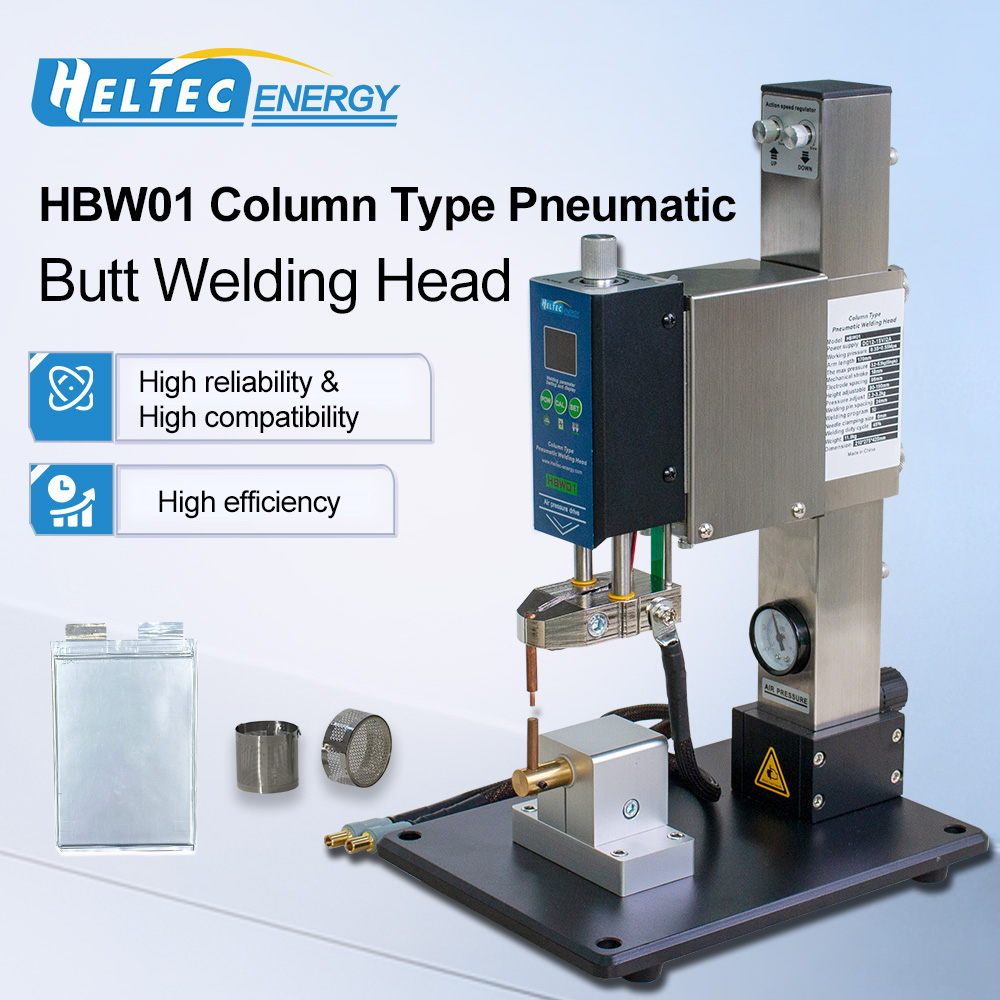

Spot welder Accessories - Spot Welding Head

Pneumatic Flat Welding Head

Pneumatic Butt Welding Head

Technical advantages

Energy saving and efficient: Low instantaneous power consumption from the power grid, high power factor, minimal impact on the power grid, and energy-saving.

Good welding quality: The welding points are firm, without discoloration, saving polishing process and high efficiency; The output voltage is stable and has good consistency, which can ensure the consistency of the welding product effect.

Long electrode life: Compared to traditional spot welding machines, the electrode life can be extended by more than twice, reducing the cost of use.

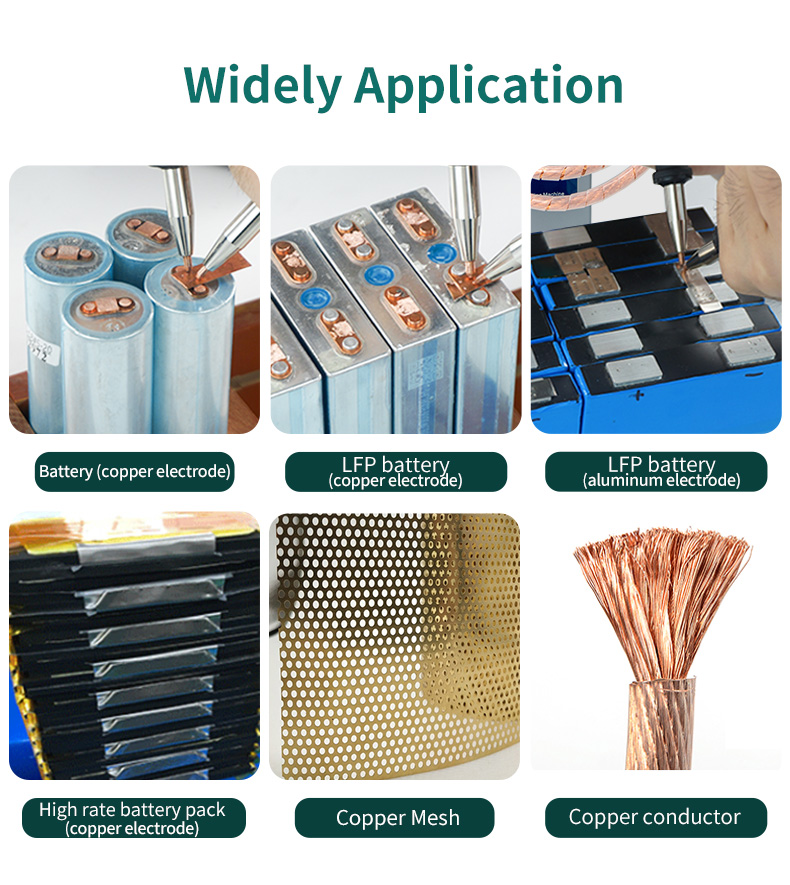

Strong adaptability: Widely applicable to welding materials, suitable for non-ferrous metals and alloy materials such as copper, aluminum, stainless steel, nickel, etc; Has good adaptability to work pieces of different thicknesses and shapes.

Model Selection Table

|

SKU |

HT-SW01A |

HT-SW01A+ |

HT-SW01B |

HT-SW01D |

HT-SW01H |

HT-SW02A |

HT-SW02H |

HT-SW03A |

HT-SW33A |

HT-SW33A+ |

|

Principle |

DC energy storage |

DC energy storage |

DC energy storage |

DC energy storage |

DC energy storage |

DC energy storage |

DC energy storage |

AC transformer |

DC energy storage |

DC energy storage |

|

Output Power |

10.6KW |

11.6KW |

11.6KW |

14.5KW |

21KW |

36KW |

42KW |

6KW |

27KW |

42KW |

|

Output Current |

2000A (Max.) |

2000A (Max.) |

2000A (Max.) |

2500A (Max.) |

3500A (Max.) |

6000A (Max.) |

7000A (Max.) |

1200A (Max.) |

4500A (Max.) |

7000A (Max.) |

|

Standard Welding Tools |

1.70A(16mm²) split welding pen; |

1.70B(16mm²) integrated welding pen; |

1.70B(16mm²) integrated welding pen; |

1.73B(16mm²) integrated welding pen; |

1.75 (25mm²) split welding pen; |

75A(35mm²) split welding pen |

1. 75A(50mm²) split welding pen |

1.73B(16mm²)integrated welding pen; |

A30 Pneumatic spot welding device. |

A30 Pneumatic spot welding device. |

|

Pure nickel welding |

0.1~0.15mm |

0.1~0.15mm |

0.1~0.2mm |

0.1~0.3mm |

0.1~0.4mm |

0.1~0.5mm |

0.1~0.5mm |

0.1~0.2mm |

0.15~0.35mm |

0.15~0.35mm |

|

Nickel plating welding |

0.1~0.2mm |

0.1~0.25mm |

0.1~0.3mm |

0.15~0.4mm |

0.15~0.5mm |

0.1~0.6mm |

0.1~0.6mm |

0.1~0.3mm |

0.15~0.45mm |

0.15~0.45mm |

|

Pure nickel welding |

/ |

/ |

/ |

/ |

/ |

0.1~0.2mm |

0.1~0.3mm |

/ |

0.1~0.2mm |

0.1~0.2mm |

|

Nickel aluminum composite sheet welding |

/ |

/ |

/ |

/ |

0.1~0.15mm |

0.1~0.2mm |

0.15-0.4mm |

/ |

0.1~0.3mm |

0.1~0.3mm |

|

Copper welding LFP Copper electrode (with flux) |

/ |

/ |

/ |

/ |

/ |

0.1~0.3mm |

0.15~0.4mm |

/ |

0.1~0.3mm |

0.1~0.3mm |

|

Power Supply |

AC 110~220V |

AC 110~220V |

AC 110~220V |

AC 110~220V |

AC 110~220V |

AC 110 or 220V |

AC 110 or 220V |

AC 110 or 220V |

AC 110 or 220V |

AC 110 or 220V |

|

Output Voltage |

DC 5.3V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

DC 6.0V(Max.) |

|

Energy Storage Charging Current |

2.8A(Max.) |

2.8A(Max.) |

4.5A(Max.) |

4.5A(Max.) |

6A(Max.) |

15A(Max.) |

15A(Max.) |

No charging required |

15A -20A |

15A -20A |

|

First Charging Time |

30~40 min |

30~40 min |

30~40 min |

30~40 min |

About 18 min |

About 18 min |

About 18 min |

No charging required, plug in to use |

About 18 min |

About 18 min |

|

Trigger Mode |

AT: Automatic induction trigger |

AT: Automatic induction trigger |

AT: Automatic induction trigger |

AT: Automatic induction trigger |

AT: Automatic induction trigger |

AT: Automatic induction trigger |

AT: Automatic induction trigger |

MT: Foot pedal trigger |

MT: Foot pedal trigger |

MT: Foot pedal trigger |

|

On-resistance/Nickel Sheet Resistance Measurement Function |

× |

× |

× |

× |

× |

× |

√ |

× |

× |

× |

|

Voltage Test Function |

× |

√ |

× |

× |

× |

× |

× |

× |

× |

× |

Battery Spot Welding Machine Application Area

- Spot welding of Lithium iron phosphate battery,Ternary lithium battery,nickel steel.

- Assemble or repair battery packs and portable sources.

- Production of small battery packs for mobile electronic devices

- Welding of lithium polymer battery,cellphone battery,and protective circuit board.

- Spot welding leaders to different metal projects,such as iron,stainless steel,brass,nickel,molybdenum and titanium.

Contact Us

If you have purchasing intentions or cooperation needs for our products, please feel free to contact us at any time. Our professional team will be dedicated to serving you, answering your questions, and providing you with high-quality solutions.

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Nancy: nancy@heltec-energy.com / +86 184 8223 7713