Introduction:

The HT-BCT50A4C four channel lithium battery capacity tester launched by HELTEC ENERGY, as an upgraded version of the HT-BCT50A, breaks through by expanding the single channel to four independent operating channels. It not only greatly improves testing efficiency, but also becomes a core tool for battery research and development, production, and quality inspection scenarios with high cost-effectiveness advantages.

Wide range adjustable charging and discharging capability

The battery capacity tester voltage range: Supports voltage range of 0.3-5V, compatible with various types of lithium batteries such as lithium titanate, ternary, and lithium iron phosphate.

Current range: Both charging and discharging currents can be flexibly adjusted within the range of 0.3-50A. The maximum current for a single channel is 50A, and when four channels are connected in parallel, it can achieve a super high current of 200A for charging and discharging (with consistent parameters), meeting the testing requirements for batteries with capacities ranging from 1-2000Ah.

Accuracy guarantee: The voltage and current accuracy can reach ± 0.1%, and it is calibrated with Fluke 8845A standard voltage source and Gwinstek PCS-10001 standard current source to ensure long-term stable and reliable data.

Multi channel independent and parallel operation

The battery capacity tester with four channel isolation design: Each channel works independently and supports simultaneous testing of batteries of different specifications to avoid mutual interference.

Flexible parallel mode: When the channel parameters are consistent, it can be used in parallel, easily achieving 200A high current testing without disassembling the battery pack connectors, improving testing efficiency.

Multi functional testing mode and intelligent operation

Diversified work modes

The battery capacity tester basic mode: covering the single mode of charging, discharging and standing to meet the requirements of basic capacity test.

Cycle mode: Supports 1-5 cycles of testing (such as "charge discharge charge" as 1 cycle), and can set the cycle cut-off voltage and settling time (default 5 minutes) to evaluate the battery cycle life.

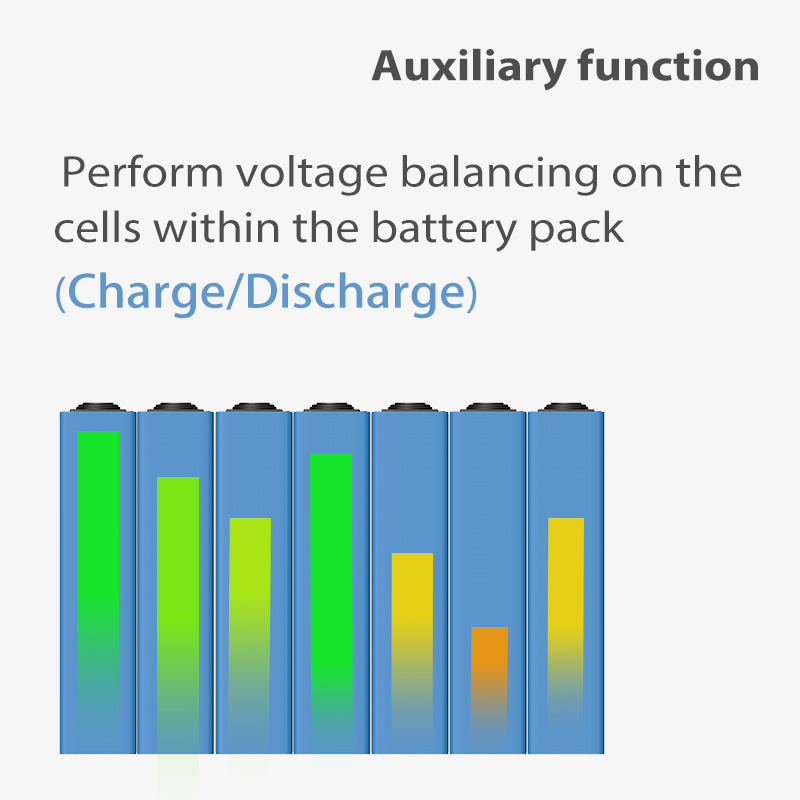

Voltage balance mode: Achieving cell voltage balance through constant voltage discharge requires setting a balance target voltage (10mV higher than the current battery voltage), discharge current (recommended 0.5-10A), and end current (recommended 0.01A) to optimize battery pack consistency.

Human Computer Interaction and Data Management

The battery capacity tester operation interface: equipped with encoding switch (rotation mode, press to set parameters) and "start/pause" button, supporting Chinese/English operation interface, compatible with Windows XP and above systems, data export and firmware upgrade through USB interface.

Real time monitoring: Dual display screens synchronously display parameters such as voltage, current, capacity, temperature, and charge discharge curves (yellow for voltage curve, green for current curve), automatically warning in case of abnormal fluctuations, facilitating real-time analysis of battery performance.

Comprehensive security protection and reliable design

Multiple protection mechanisms

Battery protection: The battery capacity tester equipped with overvoltage protection (preventing charging voltage from exceeding the limit), reverse connection protection (avoiding reverse connection of battery positive and negative poles), and disconnection protection (detecting abnormal battery connections).

Equipment protection: Built in temperature controlled fan, starts cooling at 40 ℃, triggers overheating protection at 83 ℃; Independent air duct design improves heat dissipation efficiency and extends equipment lifespan.

Operation warning: A dedicated person must be on duty during the testing process, and the crocodile clip must be correctly clamped to the battery terminal ear (the contact area of the large clip should be sufficient, and the small clip should be clamped to the bottom of the terminal ear). It is strictly prohibited to clamp screws, nickel strips, etc. to avoid testing interruption or data deviation.

Structure and compatibility

The battery capacity tester Compact body: size 620 × 105 × 230mm, weight 7kg, convenient for laboratory or production line deployment.

Power adaptation: Supports AC200-240V 50/60Hz power supply, can be customized in advance when a 110V power supply is required.

Widely applicable fields

Battery research and development: used for capacity calibration, cycle performance testing, and consistency analysis of new lithium batteries.

Production quality inspection: Suitable for batch testing of power battery packs (such as electric vehicles and energy storage systems) and consumer batteries (such as 18650 cells), supporting parallel testing to improve production capacity.

Repair and maintenance: Help detect the health status of retired batteries and screen for reusable cells.

Heltec Energy Battery Capacity Tester

Heltec Energy has always been committed to providing diversified battery testing solutions to global customers. In addition to the HT-BCT50A4C four channel lithium The battery capacity tester, we also have testing equipment covering all categories of lead-acid batteries, nickel hydrogen batteries, and lithium batteries (including ternary lithium, lithium iron phosphate, lithium titanate, etc.), supporting single cell or multiple string battery packs and wide voltage/current range adaptation. Whether in the fields of consumer electronics, power batteries, or energy storage, we can provide customized models according to customer needs to meet the precise testing needs in different scenarios.

Choosing Heltec Energy means choosing a battery testing partner that is compatible across all categories, adaptable to all scenarios, and reliable throughout the entire cycle. Welcome to contact us for a detailed product catalog and personalized solutions to jointly promote the efficient development of the new energy industry!

Request for Quotation:

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-energy.com / +86 184 8223 7713

Post time: May-16-2025