Introduction:

Welcome to the official Heltec Energy company blog! Since our establishment, we have been at the forefront of battery technology, continuously pushing the boundaries of innovation. In 2020, we introduced a mass production line of protective boards, known as Battery Management Systems (BMS), which marked a significant milestone in our journey. Looking towards the future, we are excited to share our vision of focusing on high-power spot welding machines and advanced welding techniques like laser spot welding. Join us as we explore the ways in which Heltec Energy is empowering battery manufacturing.

Welcome to the official Heltec Energy company blog! Since our establishment, we have been at the forefront of battery technology, continuously pushing the boundaries of innovation. In 2020, we introduced a mass production line of protective boards, known as Battery Management Systems (BMS), which marked a significant milestone in our journey. Looking towards the future, we are excited to share our vision of focusing on high-power spot welding machines and advanced welding techniques like laser spot welding. Join us as we explore the ways in which Heltec Energy is empowering battery manufacturing.

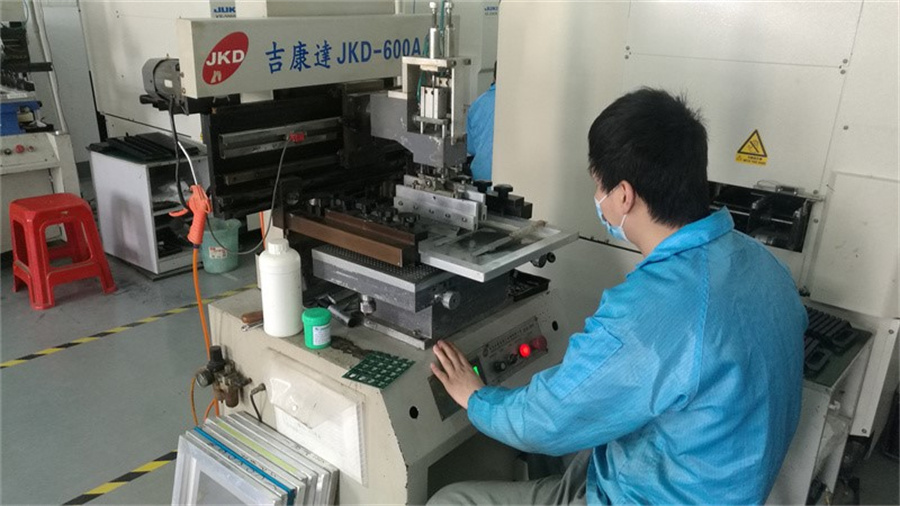

1. Introducing Mass Production of BMS:

In 2020, Heltec Energy revolutionized the battery industry by introducing a state-of-the-art mass production line of protective boards, or BMS. This expansion allowed us to provide battery pack manufacturers and suppliers with reliable and efficient BMS solutions, ensuring the safety and optimal performance of battery packs. Our BMS technology has become a trusted choice, enabling manufacturers to streamline their production processes and deliver high-quality battery packs to various industries.

2. Advancing into High-Power Spot Welding:

Recognizing the growing demand for spot welding 18650 batteries, large monomers, and other battery components, Heltec Energy is placing a strategic focus on high-power spot welding machines. With our expertise in battery accessories and deep research capabilities, we aim to develop cutting-edge spot welding solutions that enhance the efficiency, reliability, and consistency of battery pack assembly. Our high-power spot welding machines will empower manufacturers to meet the demands of modern energy storage applications.

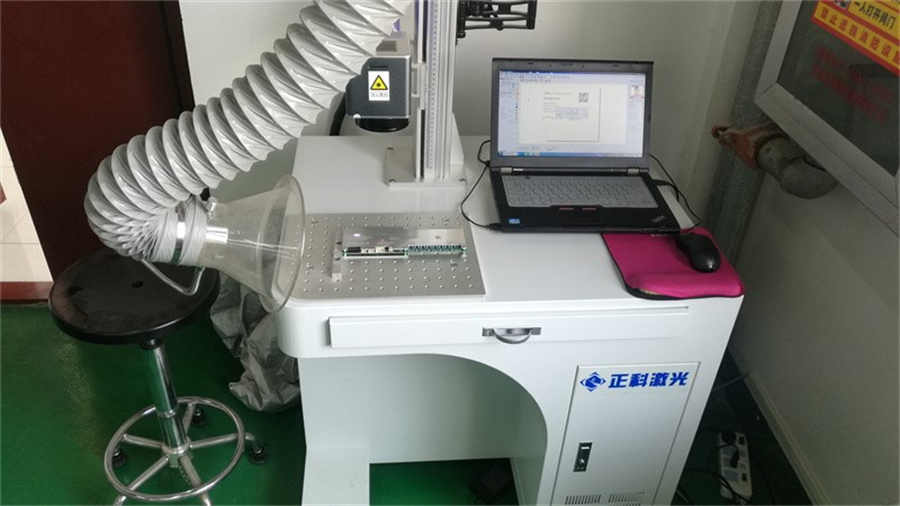

3. Embracing Laser Spot Welding:

As we look ahead, Heltec Energy is eager to explore advanced welding techniques, including laser spot welding. Laser spot welding offers precise and efficient joining of battery components, ensuring strong and durable connections. By harnessing the power of laser technology, we aim to deliver superior welding solutions that meet the stringent quality requirements of battery manufacturing. Laser spot welding will enable manufacturers to achieve enhanced production speeds, lower defect rates, and improved overall product performance.

4. One-Stop Solutions for Battery Manufacturers:

At Heltec Energy, our goal is to provide comprehensive one-stop solutions for battery pack manufacturers. From BMS to high-power spot welding machines and advanced welding techniques, we strive to meet the evolving needs of the industry under one roof. Our dedication to research and development, coupled with our customer-centric approach, ensures that we deliver tailored solutions that address specific challenges and contribute to the success of our clients.

Conclusion:

Heltec Energy continues to lead the way in battery manufacturing innovation. With the introduction of our mass production line of BMS, we have solidified our position as a trusted partner for battery pack manufacturers and suppliers. Looking forward, our focus on high-power spot welding machines and advanced welding techniques, such as laser spot welding, will revolutionize the assembly process, enabling manufacturers to produce high-quality battery packs efficiently and reliably.

Stay connected with our blog for the latest updates, industry insights, and advancements in battery technology. Contact Heltec Energy today to explore how our cutting-edge solutions can empower your battery manufacturing journey. We are excited to collaborate with you on the path to a brighter and more sustainable future.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Post time: Oct-16-2021