Introduction:

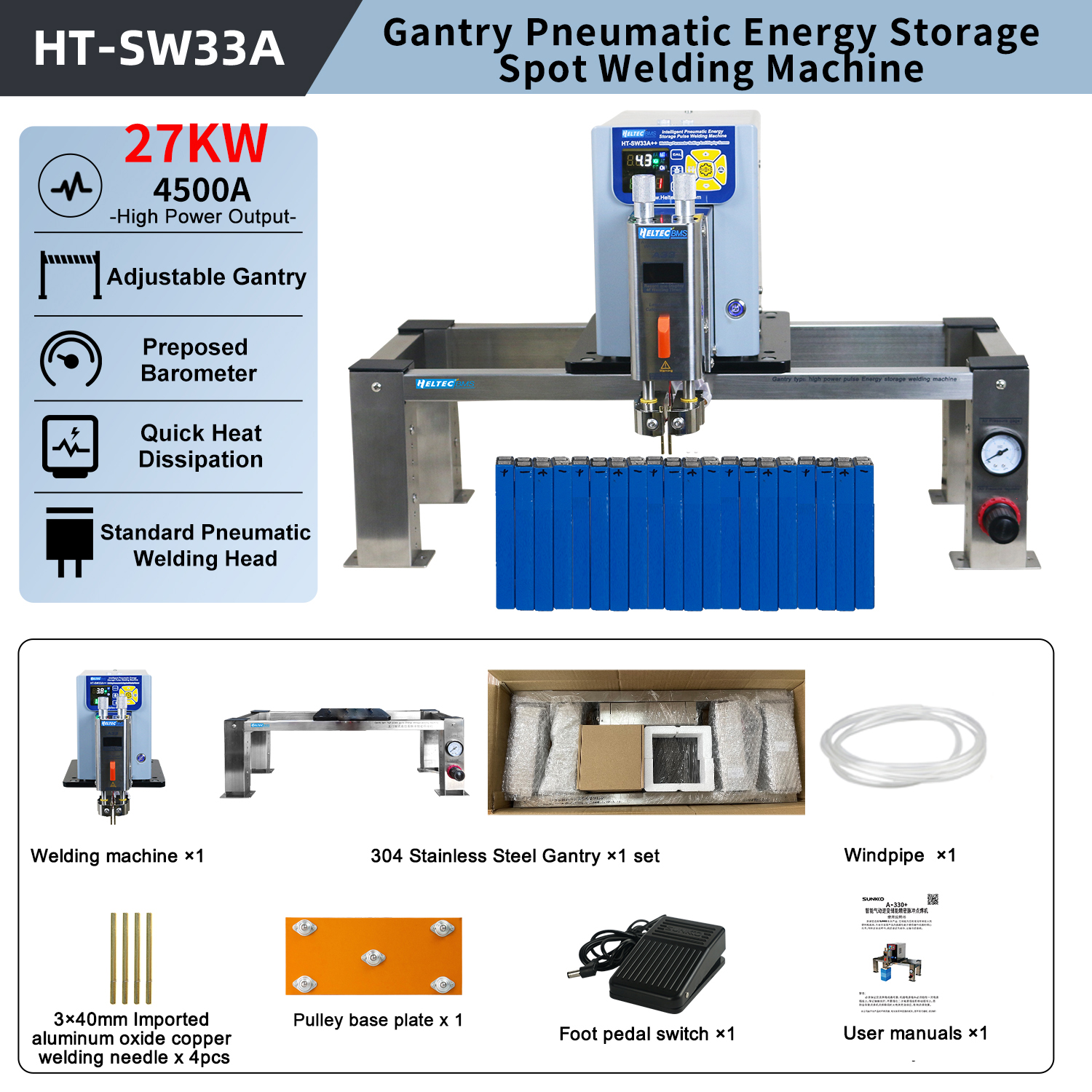

Welcome to the official Heltec Energy product blog! We’re glad to announce that we've accomplished research and design of intelligent pneumatic energy storage welding machine and we’re introducing the first model -- HT-SW33A.

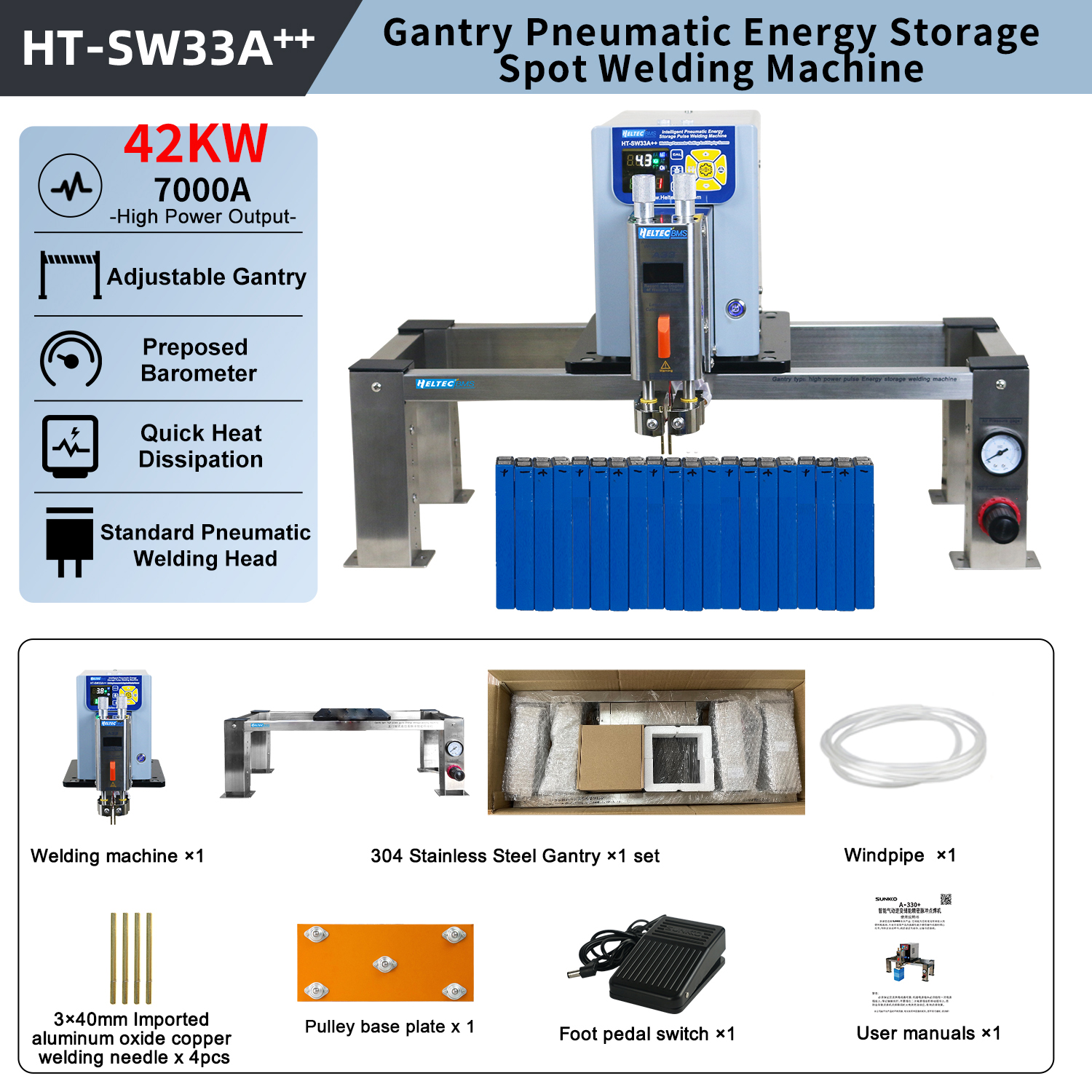

HT-SW33A Series have max peak pulse power of 42KW, with peak output current 7000A. Specially designed for welding between iron nickel materials and stainless steel materials, suitable for but not limited to the welding of ternary batteries with iron nickel and pure nickel materials.

Breakthrough:

- Pneumatic spot welding

- Gantry adjustment

- LED welding needle lighting device

- Digital LCD display

- First analog Welding calibration function with zero current output

- Original semi-automatic continuous spot welding function

- 99TH gear adjustment

- Real time current monitoring

- Intelligent cooling system

Product Parameters |

||

| Product |

33A |

33A++ |

| Output Power: |

27KW |

42Kw |

| Output Current: |

4500A |

7000A |

| Power Supply |

AC220V |

AC220V |

| Spot Welding Output Voltage: |

5.6-6.0V(DC) |

5.6-6.0V(DC) |

| Peak Welding Energy: |

540J |

840J |

| Charge current display: |

10-20A |

10-20A |

| Energy Grade: |

0-99T(0.2m/T) |

0-99T(0.2m/T) |

| Pulse Time: |

20ms |

20ms |

| Copper to copper(with flux): |

0.15-0.3mm |

0.15-0.4mm |

| Pure nickel to aluminium: |

0.1-0.2mm |

0.15-0.4mm |

| Nickel-aluminium composite sheet to aluminum: |

0.1-0.3mm |

0.15-0.4mm |

| Welding Principles: |

DC Energy Storage Super Farad Capacitor |

|

| Trigger mode: |

Foot pedal pneumatic trigger |

|

| Welding mode: |

Pneumatic press down spot welding head |

|

| Charging time: |

≤18 minutes |

|

| Dimension: |

50.5*19*34cm |

|

| Adjustable height range of gantry: |

15.5-19.5cm |

|

| Gantry frame size: |

50*19*34cm |

|

| Gantry Weight: |

10kg |

|

Sales Highlights:

- This intelligent pneumatic energy storage welding machine machine is equipped with laser red dot alignment function can quickly and accurately locate,reducing error rates and improving working efficiency.

- Equip with an intelligent cooling system to adapt to long-term uninterrupted spot welding operations.

- Compared with several other welding machines, this new product has a four-speed height adjustable gantry(Increase by 1.5cm for every step up), which suitable for various types of battery packs,the maximum welding height of the spot welder is 19cm, and the maximum width is 50cm.

- Simulated welding calibration function means this machine can simulate the spot welding and no need to spot weld samples many times and can be used for testing and adjusting the position of the weldment, adjusting welding pin pressure, and adjusting the return and press downward speed of weld head. It can reduce testing adjustments and material cost in order to realize high-quality and high efficiency spot welding.

Conclusion:

At Heltec Energy, our goal is to provide comprehensive one-stop solutions for battery pack manufacturers. From capacitor welders, to transformer welders and now, pneumatic welders, we strive to meet the evolving needs of the industry under one roof. Our dedication to research and development, coupled with our customer-centric approach, ensures that we deliver tailored solutions that address specific challenges and contribute to the success of our clients.

Heltec Energy is your trusted partner in battery pack manufacturing. With our relentless focus on research and development, coupled with our comprehensive range of battery accessories, we offer one-stop solutions to meet the evolving needs of the industry. Our commitment to excellence, tailored solutions, and strong customer partnerships make us the go-to choice for battery pack manufacturers and suppliers worldwide.

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Post time: Sep-02-2023