Battery Equalizer

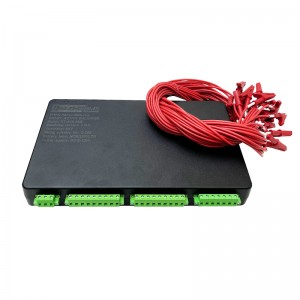

Battery Repairer 2-32S 15A 20A 25A Lithium Battery Automatic Equalizer HTB-J32S25A

Specifications

Heltec Lithium Battery Equalizer Specifitions:

- 2-24S 15A/20A /25A

- 2-32S 15A/20A/25A

Product Information

| Brand Name: | HeltecBMS |

| Origin: | Mainland China |

| Certification: | WEEE |

| Warranty: | 3 Months |

| MOQ: | 1 pc |

| Battery Type: | Ternary lithium, Lithium iron phosphate, Titanium cobalt lithium |

| Rated voltage: | DC12V |

| Repair range: | 2-24S/2-32S |

| Balance current: | 15A/20A/25A |

| Size: | 360*290*170MM |

Customization

- Customized logo

- Customized packaging

- Graphic customization

Package

1. Battery repairer *1set.

2. Anti-static bag, anti-static sponge and corrugated case.

Purchase Details

- Shipping From:

1. Company/Factory in China

2. Warehouses in United States/Poland/Russia/Brazil

Contact Us to negotiate shipping details - Payment: 100% TT is recommended

- Returns & Refunds: Eligible for returns and refunds

Features

- Rated voltage: DC12V

- Repair range: 2-32S

- Balancing current: 15A/20A/25A(adjustable)

Working Principle

① Manual Equalization

Manually set the operating voltage. When the device is in a normal state, click "Manual Balance" to modify the "Voltage Value" (the set value must be within the valid range of the current battery type), and click OK to achieve discharge balance.

② Automatic Equalization

Automatic equalization is suitable for low-speed vehicles and small-capacity battery packs. The equalization power is 5%-30%. When the device is in normal condition, click "automatic equalization" to automatically identify the highest voltage and the lowest voltage. Put it down and keep consistent with the low voltage.

③ Charging Equalization

Charge equalization generally means that the voltage of the single cells in the battery pack is carried out when the battery is half-charged.

The setting parameters of charge equalization are as follows:

Balance parameters of lithium iron phosphate:

Monomer overvoltage protection: 3.650V Monomer overvoltage recovery: 3.650V Forced equalization voltage: 3.650V

The equalization start voltage is set to the lowest value of the string voltage = V, the voltage difference of the equalization monomer: 0.005V, and the proportion of the equalization current: 5%~100%

Ternary lithium charging equalization parameters:

Monomer overvoltage protection: 4.250V Monomer overvoltage recovery: 4.200V Forced equalization voltage: 4.250V

Equalization start voltage: 4.000V Equalization monomer voltage difference: 0.005V Equalization current ratio: 5%~100%

When charging equalization, the "battery negative pole" on the front panel of the machine must be connected to the battery pack's general negative pole, the charger negative pole is connected to the machine's front panel "charging negative pole", and the charger's positive pole is connected to the battery positive pole. Before entering the balanced state, the charging current must not exceed 25A, the charging current does not exceed 5A when it reaches a balanced start (lithium iron phosphate 3.450V/ternary lithium 4.00V), and the effect of small current balance will be better.

Model Selection

| Technical Index | Product Model | |||||

| Model | HTB-J24S15A | HTB-J24S20A | HTB-J24S25A | HTB-J32S15A | HTB-J32S20A | HTB-J32S25A |

| Applicable Battery Strings | 2-24S | 2-32S | ||||

| Applicable Battery Type | LFP/NCM/LTO | |||||

| Max Balancing Current | 15A | 20A | 25A | 15A | 20A | 25A |

| Balance parameters of lithium iron phosphate | Monomer overvoltage protection: 3.65V | |||||

| Monomer overvoltage recovery: 3.65V | ||||||

| Forced equalization voltage: 3.65V | ||||||

| Equalization monomer voltage difference: 0.005V | ||||||

| Proportion of the equalization current: 5%~100% | ||||||

| Balance parameters of ternary lithium | Monomer overvoltage protection: 4.25V | |||||

| Monomer overvoltage recovery: 4.2V | ||||||

| Forced equalization voltage: 4.25V | ||||||

| Equalization start voltage: 4V | ||||||

| Equalization monomer voltage difference: 0.005V | ||||||

| Equalization current ratio: 5%~100% | ||||||

| Size(cm) | 36*29*17 | |||||

| Weight(kg) | 6.5 | 9.5 | ||||

* We keep upgrading products to meet requirements of our clients, please contact our sales person for more accurate details.

Note

① Before balancing, please check whether the minimum voltage is lower than the battery over-discharge voltage. If it is lower than the battery over-discharge voltage, please charge the battery first. Balance the battery after it is fully charged, the effect will be better.

② During charging equalization, the "battery negative pole" on the front panel of the machine must be connected to the negative pole of the whole battery pack, the negative pole of the charger is connected to the "charge negative pole" on the front panel of the machine, and the positive pole of the charger is connected to the positive pole of the battery. The charging current shall not exceed 25A before entering the equilibrium state, and the charging current shall not exceed 5A when reaching equilibrium (lithium iron phosphate 3.45V/ternary lithium 4V). Small current balance effect will be better.

③ Optional power supply

- 0-120V System Usage (for up to 24S); 0-135V System Usage (for up to 32S).

- Single-phase 220V Power Supply.

- Current parameter: 0-8A/10A.

Video

Product Instruction:

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713