Capacitor Welding Machine

Battery Spot Welder HT-SW02H 42KW Capacitor 18650 Battery Welding Machine

Specifications:

- 36KW 6000A (HT-SW02A Spot Welder)

- 42KW 7000A (HT-SW02H Spot Welder)

Product Information

| Brand Name: | HeltecBMS |

| Applicable Industries: | Machinery Repair Shops/Home Use/Retail/DIY |

| Origin: | Mainland China |

| Certification: | CE/WEEE |

| Warranty: | One year |

| MOQ: | 1 pc |

| Usage: | Spot welding/Resistance measurement |

Customization

- Customized logo

- Customized packaging

- Graphic customization

Package

1. Battery spot welder *1set.

2. Pedal switch *1set

3. spot welding pen *1set

4. open-end wrench *1set

5. spot welding electrode

6. Power cord

7. Samples of nickel sheet

8. Anti-static bag, anti-static sponge and corrugated case.

Purchase Details

- Shipping From:

1. Company/Factory in China

2. Warehouses in United States/Poland/Russia/Brazil

Contact Us to negotiate shipping details - Payment: 100% TT is recommended

- Returns & Refunds: Eligible for returns and refunds

Advantages:

- Discharge balance, no risk of overloading.

- Fast and simultaneously balancing.

- Constant resistance 1 ohm discharge balancing.

Features:

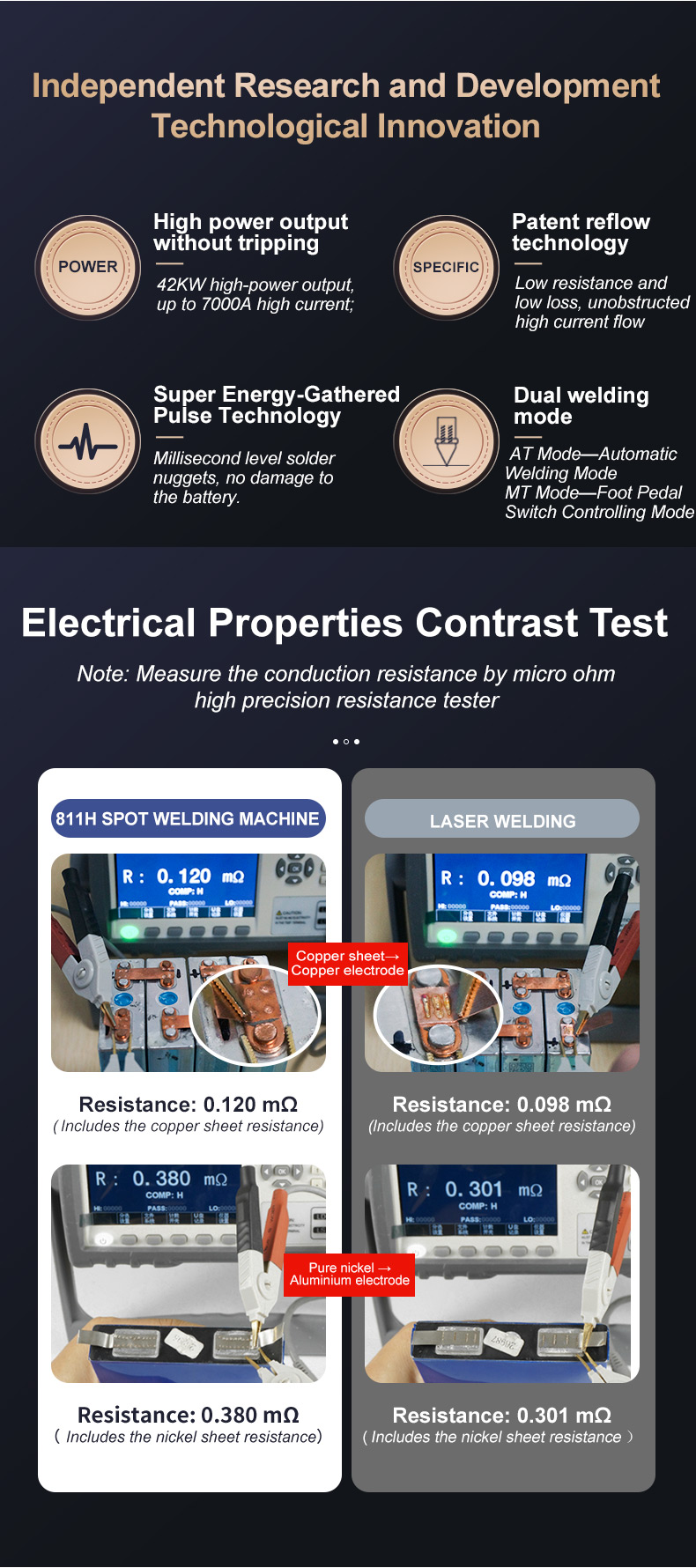

- Peak welding current 6000A/7000A

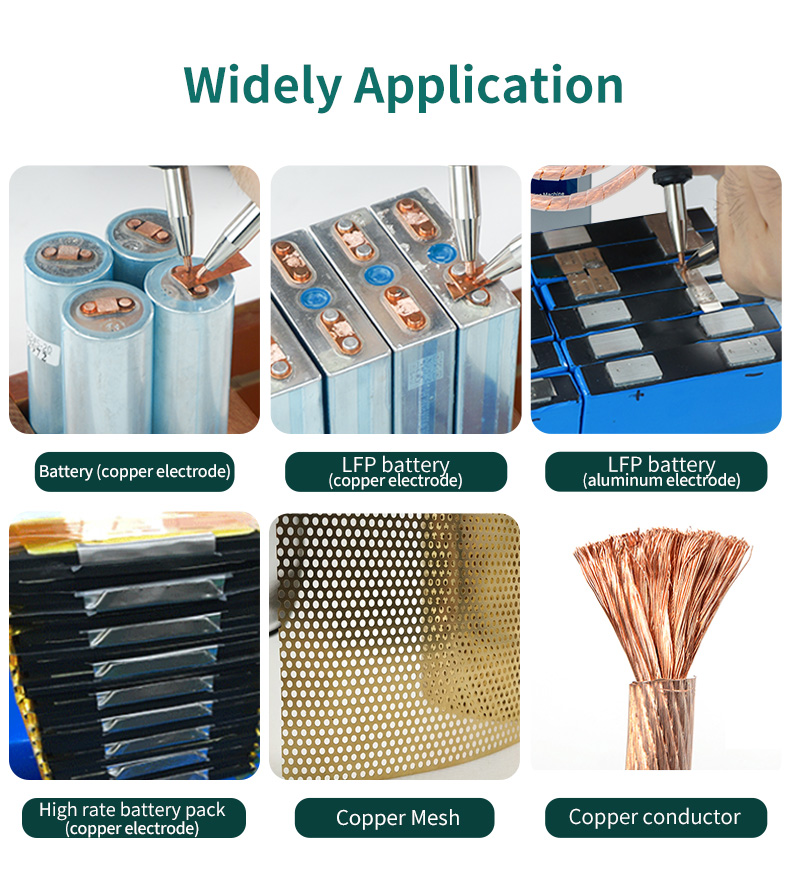

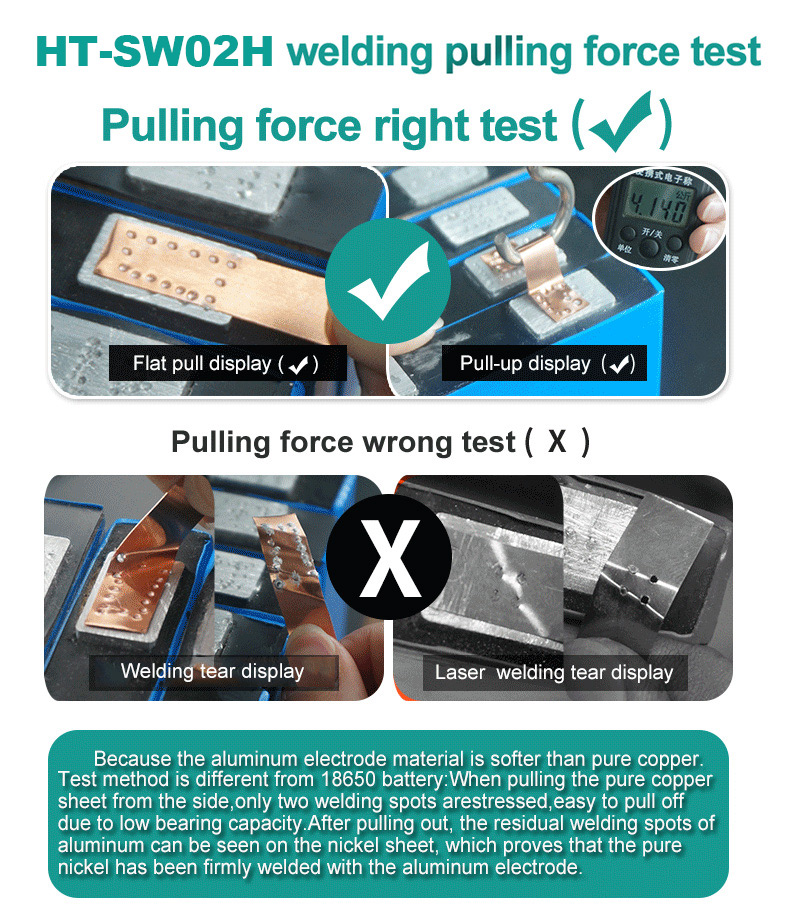

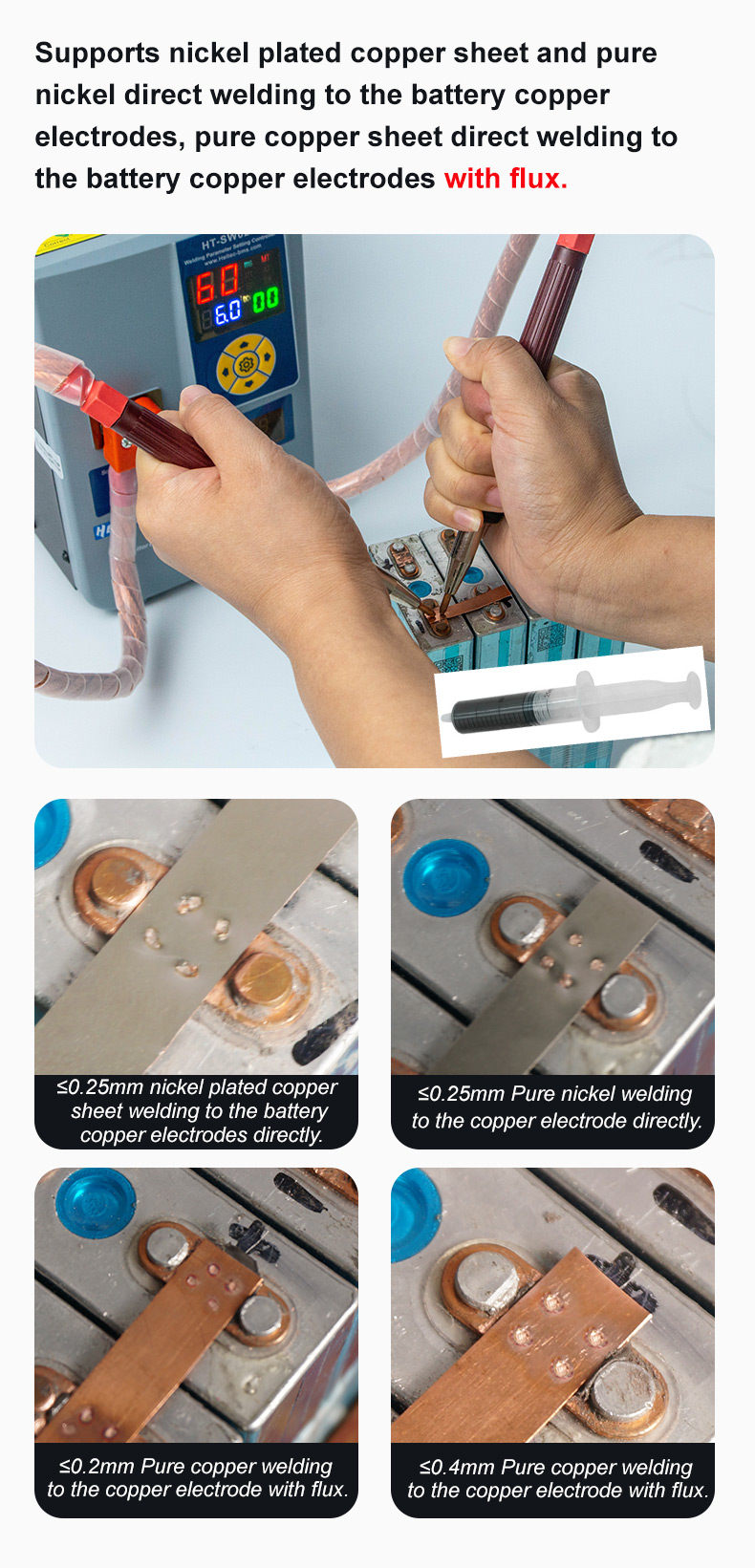

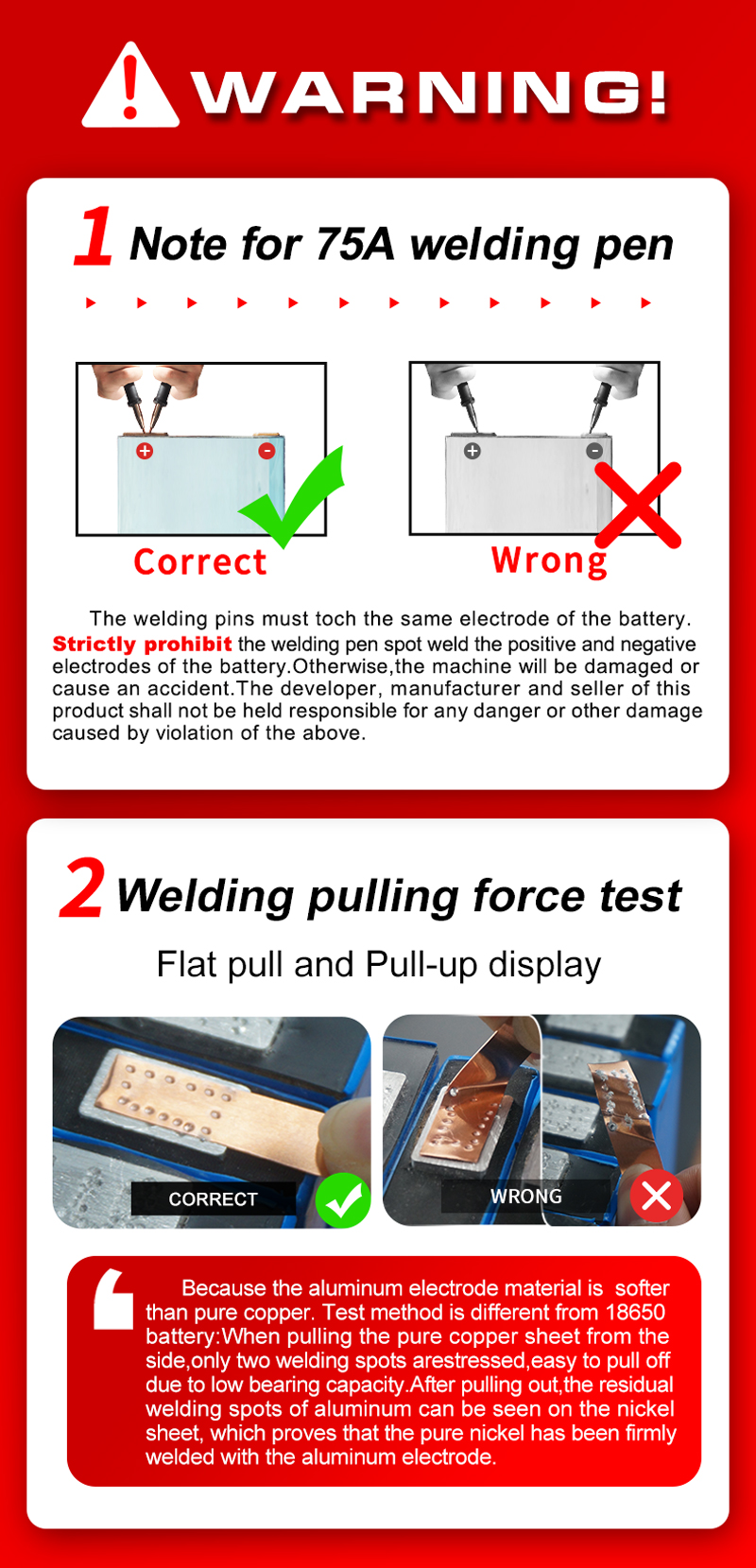

- Welding copper, aluminum and nickel conversion sheet

- Resistance measurement

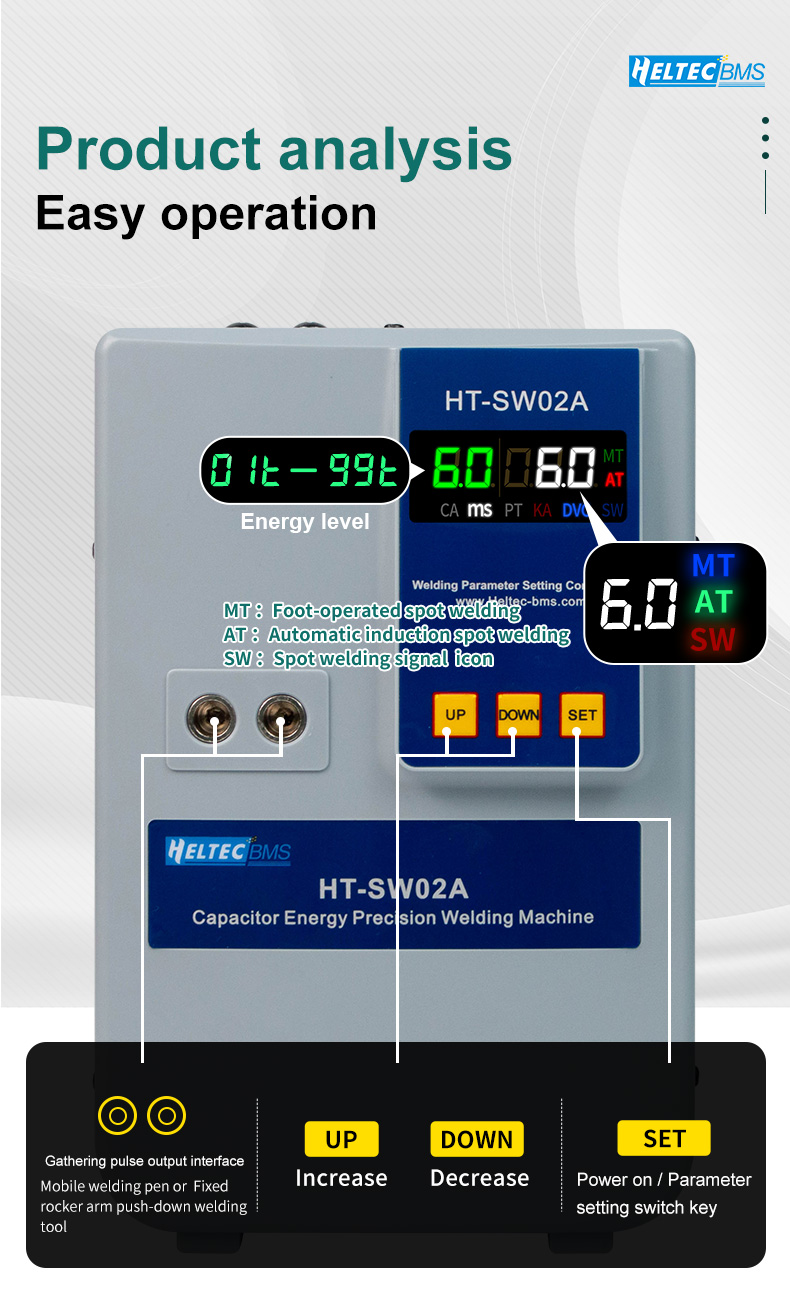

- AT/MT welding mode

- Parameters visual display

Model Selection

SW01+SW02 Series Performance Comparison:

| Heltec Spot Welder SW01+SW02 Series Performance Comparison | |||||||

| Model | HT-SW01A | HT-SW01A+ | HT-SW01B | HT-SW01D | HT-SW01H | HT-SW02A | HT-SW02H |

| 73SA Down Pressing Rocker Arm |

× | √ | √ | √ | √ | √ | √ |

| Standard Welding Pen Model |

70A Separate | 70BN Integrated | 70BN Integrated | 73B Integrated |

75A (25mm²) Separate | 75A (35mm²) Separate | 75A (50mm²) Separate |

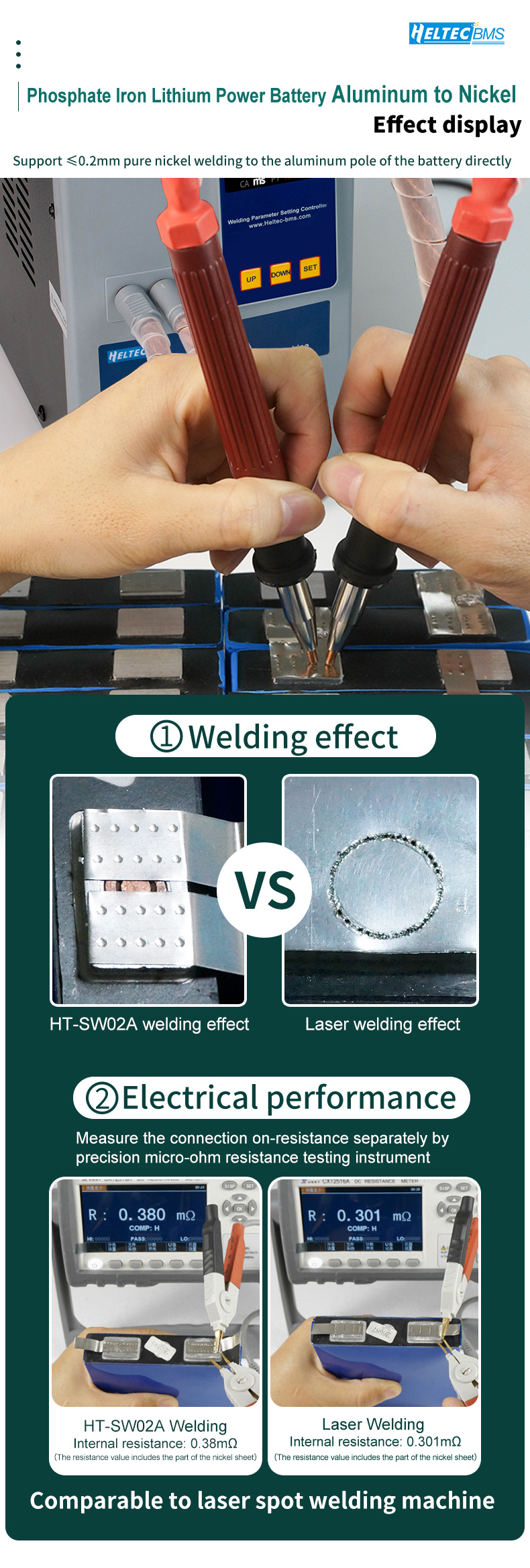

| Pure Nickel Welding to LFP on Aluminum Electrode |

× | × | × | × | √ | √ | √ |

| Pure Nickel THK (Welding Pen) | ≤0.2mm | ≤0.25mm | ≤0.25mm | ≤0.3mm | ≤0.4mm | ≤0.4mm | ≤0.4mm |

| Nickelage/Stainless Steel THK (Welding Pen) | ≤0.25~0.3mm | ≤0.3mm | ≤0.3mm | ≤0.4mm | ≤0.5mm | ≤0.6mm | ≤0.6mm |

| Pulse Power (Peak) | 11.6KW | 11.6KW | 11.6KW | 12KW | 21KW | 36KW | 42KW |

| Output Current (Peak) | 2000A | 2000A | 2000A | 2500A | 3500A | 6000A | 7000A |

| Pulse Time (Max) | 5ms | 10ms | 10ms | 20ms | 20ms | 20ms | 20ms |

| Charging Time | 30~40min | 20~30min | 20~30min | 20~30min | About 18min | About 18min | About 18min |

| MT Pedal Precision Spot Welding |

× | × | √ | √ | √ | √ | √ |

| AT Auto Trigger Spot Welding |

√ | √ | √ | √ | √ | √ | √ |

| Voltage Test Function | × | √ | × | × | × | × | × |

| Resistance Measurement | × | × | × | × | × | × | √ |

| Real Welding Current Display |

× | × | √ | √ | √ | √ | √ |

| Memory Function | × | × | × | √ | √ | √ | √ |

* We keep upgrading products to meet requirements of our clients, please contact our sales person for more accurate details.

Videos:

HT-SW02A

HT-SW02H

Request for Quotation:

Jacqueline: jacqueline@heltec-bms.com / +86 185 8375 6538

Sucre: sucre@heltec-bms.com / +86 136 8844 2313

Nancy: nancy@heltec-bms.com / +86 184 8223 7713