Introduction:

Welcome to Heltec Energy industry blog! As a leader in lithium battery solutions industry, we are dedicated to providing comprehensive one-stop solutions for battery pack manufacturers and suppliers. With a strong focus on research and development, as well as the production of battery accessories, Heltec Energy is committed to empowering the industry by offering innovative products and services. After years of development, battery welding equipment is constantly upgraded, the quality of spot welding is also constantly improved. But we also often see a variety of spot welders in the same production plant together, playing their respective roles. We will go from the principle of a variety of spot welding machine to understand their performance.

Application:

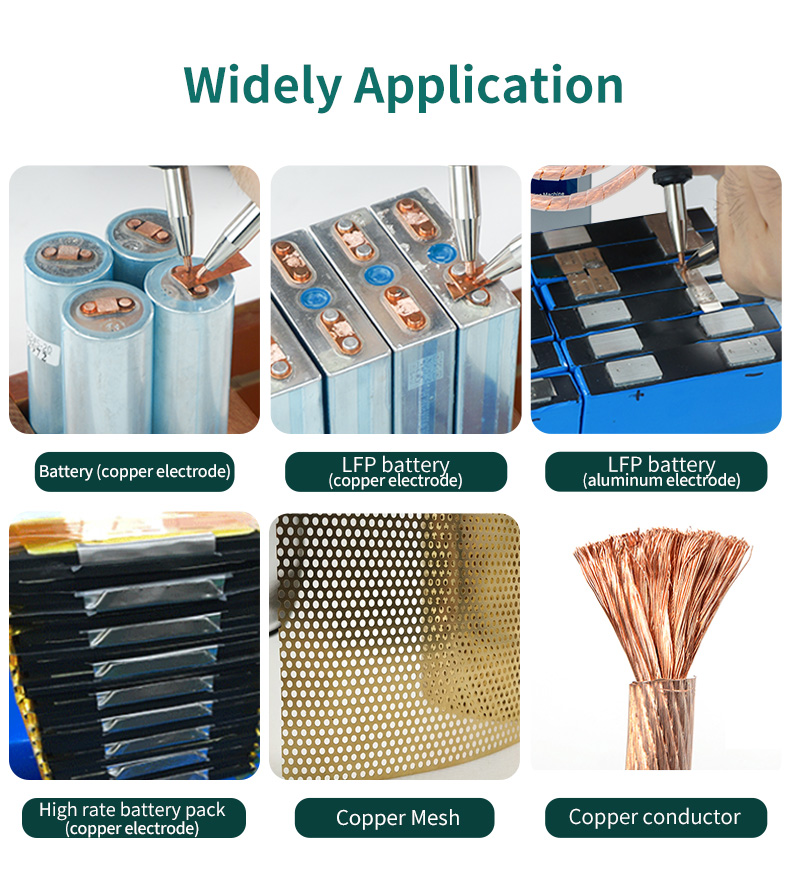

Spot welding is mainly used for thin plate welding. The process generally consists of pre-pressurisation to ensure good contact between the work pieces; electrochemistry, which forms a molten core and plastic ring at the weld site; and power-off forging, which allows the molten core to be cooled and crystallize under sustained pressure to form a dense, non-shrinking, crack-free weld joint.

For example, the battery spot welder is a specialized equipment used in the battery manufacturing process to weld the battery cells and connecting tabs, which mainly consists of a transformer, control system, welding tongs, cooling system, and so on. The transformer is used to reduce the input voltage and increase the current, the control system controls the welding time and welding current, and uses the principle of resistance welding to generate high temperature at the welding point to achieve metal fusion, thus completing the welding between the battery cell and the connecting piece.

Our Feature:

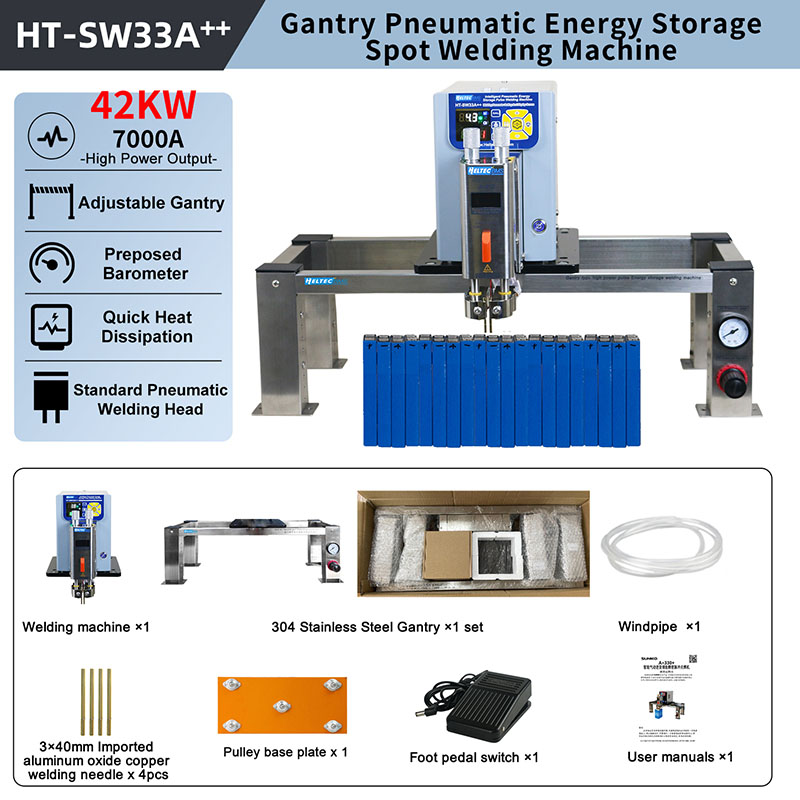

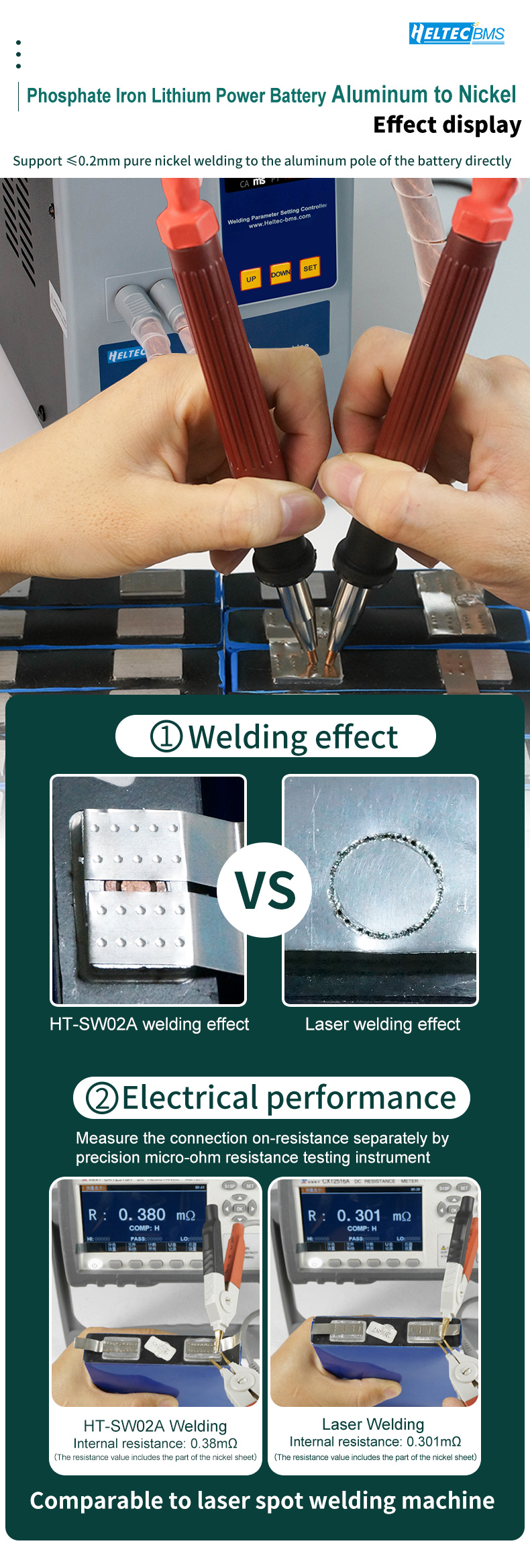

We focus on advanced welding technology for high-power spot welding machines. We currently specialize incapacitor energy storage welding machines, integrated pneumatic welding machines, gantry-type pneumatic energy storage spot welding machines, etc. Compared with cold welding, our products have stronger welding capabilities. Compared with laser welding technology, although it has the advantages of high efficiency and high precision, our products have lower equipment cost and less technical requirements for operators.

Conclusion:

The above is the introduction of the working principle and application of spot welding machine, next blog we will continue to introduce the characteristics and application of capacitor energy storage welding machines and pneumatic spot welding machine, please look forward to it!

If you have any questions or would like to learn more, please don't hesitate to reach out to us.

Post time: Nov-15-2023